It’s easier said than done to pivot from daily operations to fulfill an urgent product need. We’ve seen this first hand during the coronavirus pandemic.

Large automotive manufacturers have the scale, capital, and skilled workforce to shift from making SUVs to making ventilators in a matter of a few weeks. Smaller companies may be able to meet other needs based on their capabilities, equipment and material supplies.

This ability to step up not only demonstrates an organization’s determination, flexibility and innovativeness, it shows a culture able to competently face adversity as well. It also highlights the importance of strategic investments in technology and automation to cope with production challenges during a crisis.

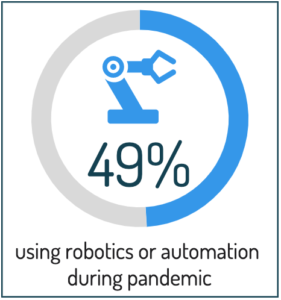

According to a recent Pulse survey, of the companies who are making a pivot in their business in response to the coronavirus outbreak, 49% are using robotics or automation to help frontline workers produce new products and deal with any operational issues.

In an interview with Industry Week, product manager Martin Petrick of Rockwell Automation stated, “flexible manufacturing setups with higher levels of automation makes operator support easier. Also, modular equipment that can be easily reconfigured is immensely helpful. Any technology that allows the people who set up and operate equipment to be guided, in order to augment their skillsets, is extremely helpful.”

Before the pandemic, automation had been gradually replacing or augmenting human work in a range of jobs, from call centers to warehouses, as businesses looked to cut labor costs and improve profit.

If social distancing directives continue to some degree as the crisis subsides, automation could be introduced to more industries. CLICK TO TWEET

However, as more manufacturers think harder about technology and automation in their companies, workers need not panic too much for now. There may be a belief among some people that a new wave of automation is upon us thanks to smarter artificial intelligence and more sophisticated robots, but that’s likely a little premature.

Despite advancements in technology and production, workers will still be needed as many machines are still far away from matching human intelligence, dexterity and decision-making.

One of the big takeaways from research done by Boston University’s James Bessen is that “automation tends to eliminate some of the tasks that constitute a particular job, but not all of them. Rarely are entire jobs automated away, although they might change a lot. And even jobs that disappear might experience an extremely long decline.”

While automation will continue to make inroads in manufacturing and other businesses, those companies are still going to need workers to operate much of the equipment, crisis or no crisis.

Related Items

Catalyst Connection has developed Manufacturers’ Guide to Robotics to serve as a tool to help small manufacturers explore the adoption of robotics in their facilities.

Embracing technology within the manufacturing process can alleviate your challenges and expand your capabilities.

As we look to the future of connected devices and the technology behind them, we need to consider their cybersecurity implications.